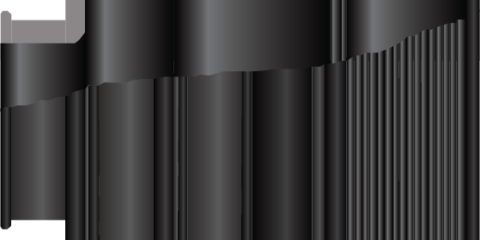

Econoseal

The Econoseal is a simple cast-in pipe- to-manhole connector that offers an easy installation process in precast production facilities and in the field for contractors. The key-lock is integrally cast-in during the production process providing a secure seal for storm water and sanitary collection systems.

Document Downloads

Download Product Literature

How It Works

- Reusable mandrel tool holds the connector in place during the casting process.

- Connector is folded inward towards center of structure before shipping to job site.

- The pipe is beveled at the job site.

- Lubricant is applied to the connector and the pipe barrel.

- Pipe is inserted into connector by contractor.

Why It's Better

- No special torque tools or take-up clamps required.

- Durable and reusable mandrel forms.

- Integrally cast into the structure at time of casting.

- Contractor can save time and money by backfilling immediately.

Where To Use

- Manholes

- Wet wells

- Stormwater structures

Meets or Exceeds

- ASTM C 923: Standard Specification for Resilient Connectors Between Reinforced Concrete Manhole Structures, Pipes, and Laterals

- ASTM C 1478: Standard Specification for Storm Drain Resilient Connectors Between Reinforced Concrete Storm Sewer Structures, Pipes and Laterals

- ASTM C 1244: Standard Test Method for Concrete Sewer Manholes by the Negative Air Pressure (Vacuum) Test

| TYPICAL TEST RESULTS for ECONOSEAL (as in ASTM C 923 and C 1478) | |||

|---|---|---|---|

| Test | ASTM Test Method | Test Requirements | Typical Result |

| CHEMICAL RESISTANCE; 1N SULFURIC ACID and 1N HYDROCHLORIC ACID | D 534, AT 22ºC FOR 48 HRS | NO WEIGHT LOSS NO WEIGHT LOSS | NO WEIGHT LOSS NO WEIGHT LOSS |

| TENSILE STRENGTH | D 412 | 1200 PSI, MIN | 2100 PSI |

| ELONGATION AT BREAK | D 412 | 350%, MIN | 600% |

| HARDNESS | D 2240 (SHORE A DUROMETER) | ±5 FROM THE MANUFACTURER’S SPECIFIED HARDNESS | <2 |

| ACCELERATED OVEN-AGING | D 573, 70± 1ºC FOR 7 DAYS | DECREASE OF 15%, MAX. OF ORIGINAL TENSILE STRENGTH, DECREASE OF 20%, MAX. OF ELONGATION | -13% TENSILE CHANGE, -14% ELONGATION CHANGE |

| COMPRESSION TEST | D 395, METHOD B, AT 70ºC FOR 22 HRS | DECREASE OF 25%, MAX. OF ORIGINAL DEFLECTION | 13% |

| WATER ABSORPTION | D 471 IMMERSE 0.75 BY 2-IN.SPECIMEN IN DISTILLED WATER AT 70ºC FOR 48 hrs | INCREASE OF 10%, MAX. OR ORIGINAL BY WEIGHT | 3.50% |

| OZONE RESISTANCE | D 1171 | RATING 0 | PASS |

| LOW-TEMP, BRITTLE POINT | D 746 | NO FRACTURE AT -40ºC | PASS |

| TEAR RESISTANCE | D 624, METHOD B | 200 LBF/IN. (MIN.) | 450 LBF/IN. |

A watertight flexible pipe-to-manhole connector shall be employed in the connection of the sanitary sewer and/or stormwater pipe to precast manholes or other structures.

The connector shall be ECONOSEAL as manufactured by Press-Seal Corporation, Fort Wayne, Indiana, or approved equal.

The connector shall be the sole element relied on to assure a flexible watertight seal of the pipe to the structure. The rubber connector shall be constructed solely of synthetic or natural rubber, shall meet/exceed the requirements of ASTM C 923, and shall have a minimum tensile strength of 1600 psi.

The connector shall be directly cast into the structure using casting accessories available from the connector manufacturer. Selection of the proper casting accessories for the manhole and pipe requirement, and installation thereof, shall be in strict conformance with the recommendations of the connector manufacturer. Any dead end pipe stubs installed in connectors shall be restrained from movement per ASTM C 923.

The finished connection shall provide sealing to 13 psi (minimum), and shall accommodate deflection of pipe to 7 degrees (minimum) without loss of seal.

Vacuum testing shall be conducted in strict conformance with ASTM C 1244 prior to backfill. Other testing shall be conducted in strict conformance with the requirements of the connector manufacturer.

Econoseal for 4″ – 15″ Pipe Sizes

- Remove Casting Mandrel and Casting Ring from the installed ECONOSEAL Connector.

- Fold sealing member from Casting Position (toward outside of manhole) to Seal Position (toward inside of manhole).

- Manhole is ready to ship to job site for pipe installation.

- Bevel pipe 3/4” (20 mm) all around.

- Clean connector, pipe barrel, and manhole opening of any dirt or debris.

- Apply gasket lubricant to pipe barrel (at least 15”) (375 mm) and to connector.

- Center beveled pipe in connector and push pipe into manhole. Use a bar for leverage, if required, taking

care not to damage pipe or connector. - Set pipe to line and grade and back fill carefully.

Econoseal for 18in – 30in Pipe Sizes

- Remove torsion springs and casting mandrel from the installed Econoseal connector.

- Fold sealing member from casting position (toward outside of manhole) to seal position (toward inside of manhole).

- Manhole is ready to ship to job-site for pipe installation.

- Bevel pipe 3/4” (20 mm) all around.

- Clean connector, pipe barrel, and manhole opening of any dirt or debris.

- Apply gasket lubricant to pipe barrel (at least 15”) (375 mm) and to connector.

- Center beveled pipe in connector and push pipe into manhole. Use a bar for leverage, if required, taking care not to damage pipe or connector.

- Set pipe to line and grade and back fill carefully.