RFS Nitrile Pre-lubricated Gaskets

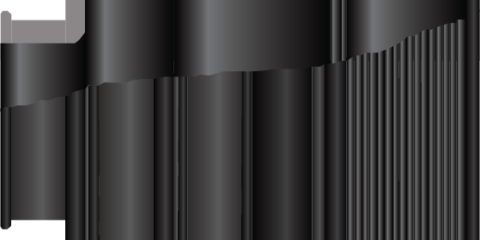

Nitrile RFS Pre-lubricated Pipe Gasket is a concrete joint gasket made from synthetic Nitrile Butadiene rubber polymer.

Document Downloads

Download Product Literature Download Box Culvert Literature

The RFS Nitrile pre-lubricated pipe and manhole gasket is an encapsulated all rubber gasket that is filled with an internal lubricant.

The unique design also helps in reducing insertion forces, virtually eliminating any twisting of the gasket or rolling out of the joint commonly found to occur in O-ring and profile gaskets.

The Nitrile RFS cross-sections are dimensionally the same as the standard RFS cross-sections.

Nitrile RFS is used when you have an application where the gasket will be exposed to petro by-products or solvent based products.

The Nitrile RFS cross-sections are the same dimension as the standard RFS cross-sections.

How It Works

- Gasket is stretched over the spigot with the tube lying flat against the spigot.

- Spigot and bell are homed with little insertion force due to the internal lubricant.

- The rolling feature fills the small annular space.

Why It's Better

- Specially developed rubber for applications where exposure to petro by-products or solvent based products might be used.

- Installs quicker by eliminating the lubrication step.

- Faster installation because no external lubricant is required, the gasket stays cleaner during handling and assembly.

Where To Use

- Manholes

- Wet wells

- Square pump and lift stations

- Stormwater structures

- On-site treatment structures

- Junction chambers

- Grease interceptors

Meets or Exceeds

This nitrile gasket meets or exceeds:

- Rubber meets ASTM C 1619 (Class D)

- CSA A 257.3

- ASTM C 443-12

“Special

Due to inherent properties of Nitrile gaskets, special considerations are noted:

- Nitrile gaskets are non-stock items, and they will require 1-3 weeks lead time for production and testing.

- Nitrile gaskets are higher durometer (harder), increasing pipe insertion forces. This hardness increases rapidly at lower temperatures, requiring special care in low-temperature installations (< 40F/4C).

- Nitrile rubber may occasionally have slight internal porosity. This is not a defect as long as the material meets all other specification requirements.

- Required splice testing strain may result in occasional splice breakage when the gasket is installed on the pipe. It is recommended that an additional quantity of gaskets (5 -10%) be ordered and supplied to compensate. In any event, Press-Seal will not be responsible for any consequent delays or damages related to this.

- Nitrile rubber hardens rapidly with age. Gaskets older than 12 months should be retested before use to ensure their continued suitability.

Special Notes Regarding NITRILE RFS GASKETS

Due to inherent properties of Nitrile gaskets, special considerations are noted:

- Nitrile gaskets are non-stock items, and they will require 1-3 weeks lead time for production and testing.

- Nitrile gaskets are higher durometer (harder), increasing pipe insertion forces. This hardness increases rapidly at lower temperatures, requiring special care in low-temperature installations (< 40F/4C).

- Nitrile rubber may occasionally have slight internal porosity. This is not a defect as long as the material meets all other specification requirements.

- Required splice testing strain may result in occasional splice breakage when the gasket is installed on the pipe. It is recommended that an additional quantity of gaskets (5 -10%) be ordered and supplied to compensate. In any event, Press-Seal will not be responsible for any consequent delays or damages related to this.

- Nitrile rubber hardens rapidly with age. Gaskets older than 12 months should be retested before use to ensure their continued suitability.

| Profile Designation | Body Height "A" | Body Width "B" | Total Width "C" | Annular Space | |

|---|---|---|---|---|---|

| Gasket | Pipe | ||||

| RFS-135 | 0.650 (16.5 mm) | 0.724 (18.4 mm) | 1.607 (40.8 mm) | 0.326 (8.3 mm) | 0.126 (3.2 mm) |

| RFS-165 | 0.755 (19.2 mm) | 0.825 (21.0 mm) | 1.954 (49.6 mm) | 0.446 (11.3 mm) | 0.146 (3.7 mm) |

| RFS - 185 | 0.798 (20.3 mm) | 0.938 (23.8 mm) | 2.110 (53.6 mm) | 0.446 (11.3 mm) | 0.146 (3.7 mm) |

| RFS - 200 | 0.825 (21.0 mm) | 0.960 (24.4 mm) | 2.130 (54.1 mm) | 0.500 (12.7 mm) | 0.146 (3.7 mm) |

| RFS-225 | 0.960 (24.4 mm) | 1.047 (26.6mm) | 2.770 (70.4 mm) | 0.525 (13.3 mm) | 0.175 (4.4 mm) |