Rail Tie Pads

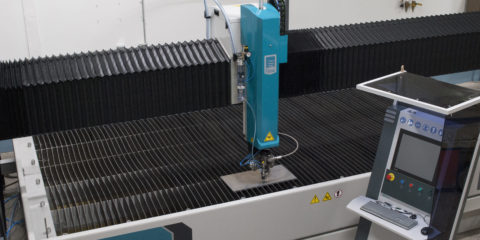

We fabricate our rail pads with two high-speed, dual-head Flow 2-Axis CNC Waterjet machines. These waterjet machines can produce up to 2,200 kgs of rubber tie pads per day. Material choices include:

- Rubber

- Masticated rubber

- Cloth inserted rubber

- HDPE

The main function of rail tie pads are to reduce fatigue cracking of the concrete railroad ties from vibration. It is believed that the impact and vibrational loads of passing trains can cause fatigue and/or failure.

By increasing the lifespan of the rail tie, Press-Seal rail tie pads provide better protection through better design. Designs come in all shapes and sizes, plus different contours to meet your requirements.

Our rail tie pads are capable of being applied to a variety of configurations and track types – mostly used in freight applications at turn outs or switches.

Transit’s will also find great value in our tie pads because of their resistance to stray current.

Some of the main benefits of our rail tie pads are:

- Excellent chemical resistance – trains could look fluids or be transporting materials that would otherwise damage the pads

- Excellent electrical resistance – stray current in freight or transit is a common occurrence that can effect the lifespan of a tie

- Superior non-weathering capabilities – the materials we manufacture pads with can stand up to many weather conditions

- Excellent abrasion resistance – eliminate the dissimilar metal and concrete tie materials from rubbing together creating an abrasive and destructive problem

- Excellent compression set – continually tested to meet and/or exceed all compression sets based off of customer requirements and/or standards

Customized Tie Pads

You might not consider the idea of having tie pads customized, but Press-Seal has the capability of creating any configuration with our state-of-the-art waterjet cutter. This machine is unmatched in its accuracy, quickness and overall speed.

It allows us to customize your pads with lettering, identification or any other configuration that meets your specific needs.

Some manufacturers will require you to drive through their materials wasting your time trying to get through the material. With our waterjet cutting services, we can automatically place pilot holes in almost any location of the tie pad.

You can always contact us with further questions regarding customization, specifications, configurations or even material types. It is our intent to be able to design, manufacture and deliver a tie pad that increases the working life of your track in both freight and transit.