Kwik Seal

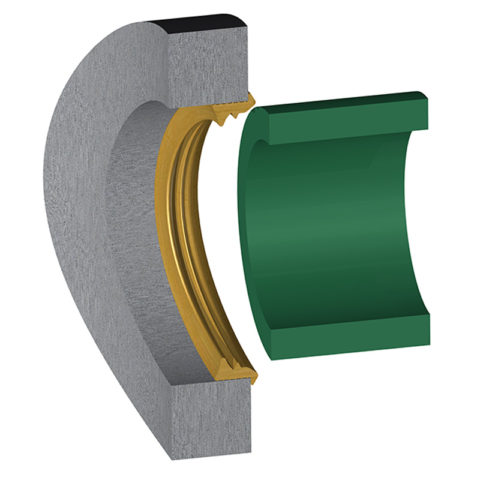

Kwik Seal is a precisely sized compression connector (pipe to manhole connector) made to fit in a cored or cast opening. The connector is placed into the opening and the pipe is pushed home. This creates a watertight seal when the connector is compressed around the pipe OD and is deformed against the manhole opening. The sealing is similar to how a pipe gasket seals pipe joints.

- Used in wastewater and stormwater systems

- Meets or exceeds all requirements of ASTM C 923, including physical properties of materials and performance testing.

Document Downloads

Download Product Literature

The Kwik Seal is a simple all-rubber compression-connector seal that makes a flexible watertight connection between pipes and concrete structures.

It offers an easy installation process in precast production facilities or in the field for contractors.

A simple and effective manhole connector for pipes entering manholes and other underground structures.

How It Works

- The connector fits into a cast or cored hole

- The pipe is beveled at the job site

- Lubricant is applied to the connector and the pipe barrel

- Pipe is inserted into connector by contractor

Why It's Better

- No special torque tools or take-up clamps required.

- Easily replaced if damaged.

- Works with a large variety of common hole sizes.

- Can be used in cast or cored holes.

- Contractor can save time and money by backfilling immediately.

Where To Use

- Manholes

- Wet wells

- Square pump and lift stations

- Stormwater structures

- On-site treatment structures

- Junction chambers

- Grease interceptors

Meets or Exceeds

Kwik Seal meets and/or exceeds all requirements of ASTM C 923, including physical properties of materials and performance testing. Performance testing includes:

- 13 PSI minimum in straight alignment

- 10 PSI at minimum 7° angle

- 10 PSI minimum under shear load of 150 lbs/in. pipe diameter

| TYPICAL TEST RESULTS for KWIK SEAL (as in ASTM C 923 and C 1478) | |||

|---|---|---|---|

| Test | ASTM Test Method | Test Requirements | Typical Result |

| CHEMICAL RESISTANCE; 1N SULFURIC ACID and 1N HYDROCHLORIC ACID | D 534, AT 22ºC FOR 48 HRS | NO WEIGHT LOSS NO WEIGHT LOSS | NO WEIGHT LOSS NO WEIGHT LOSS |

| TENSILE STRENGTH | D 412 | 1200 PSI, MIN. | 2100 PSI |

| ELONGATION AT BREAK | D 412 | 350%, MIN. | 525% |

| HARDNESS | D 2240 (SHORE A DUROMETER) | ±5 FROM THE MANUFACTURER’S SPECIFIED HARDNESS | <2 |

| ACCELERATED OVEN-AGING | D 573, 70± 1ºC FOR 7 DAYS | DECREASE OF 15%, MAX. OF ORIGINAL TENSILE STRENGTH, DECREASE OF 20%, MAX. OF ELONGATION | -13% TENSILE CHANGE, -14% ELONGATION CHANGE |

| COMPRESSION TEST | D 395, METHOD B, AT 70ºC FOR 22 HRS | DECREASE OF 25%, MAX. OF ORIGINAL DEFLECTION | 13% |

| WATER ABSORPTION | D 471 IMMERSE 0.75 BY 2-IN.SPECIMEN IN DISTILLED WATER AT 70ºC FOR 48 hrs | INCREASE OF 10%, MAX. OR ORIGINAL BY WEIGHT | 3.50% |

| OZONE RESISTANCE | D 1171 | RATING 0 | PASS |

| LOW-TEMP, BRITTLE POINT | D 746 | NO FRACTURE AT -40ºC | PASS |

| TEAR RESISTANCE | D 624, METHOD B | 200 LBF/IN. (MIN.) | 450 LBF/IN |

A watertight flexible pipe-to-manhole connector shall be employed in the connection of the sanitary sewer and/or storm water pipe to precast manholes or other structures.

The connector shall be KWIK SEAL as manufactured by Press-Seal Corporation, Fort Wayne, Indiana, or approved equal.

The connector shall be the sole element relied on to assure a flexible watertight seal of the pipe to the structure. The connector shall consist of a single rubber gasket, shall be constructed solely of synthetic or natural rubber, shall meet/exceed the requirements of ASTM C 923, and shall have a minimum tensile strength of 1600 psi.

Selection of the proper size connector for the manhole and pipe requirement, and installation thereof, shall be in strict conformance with the recommendations of the connector manufacturer. Any dead end pipe stubs installed in connectors shall be restrained from movement per ASTM C 923.

TO PREPARE STRUCTURE OPENING FOR GASKET

- Clean opening thoroughly, removing any dirt or debris.

- If needed to retain gasket in structure opening, spray TRANSTAR Contact Adhesive (caution – flammable) all around entrance area of opening at least 2-inches (50 mm) wide

TO INSTALL GASKET INTO MANHOLE

- Install gasket by squeezing into a heart shape and inserting into hole from outside of structure

- Smooth gasket around hole by working any excess rubber around the hole until gasket lies flat against hole ID

- Push gasket lip back into hole until it bottoms completely around hole

TO INSTALL PIPE INTO GASKET

- Make sure that pipe end is clean and well-beveled for at least 3/4’’ (19 mm) from end all around

- Make sure that pipe end is clean for at least 15” from end

- Apply lubricant generously to pipe and to fins of installed gasket. Make sure that entire pipe is lubricated for at least 15’’ from end

- DO NOT APPLY ANY LUBRICANT TO UNDERSIDE OF CONNECTOR

- Center pipe carefully in gasket and begin to push inward. Push straight into hole. Installation pressure will drop slightly after first fin is cleared. This locks gasket into the hole

- Continue pushing, and pressure will increase until pipe end clears gasket completely

- Move pipe inward until it clears interior plane of structure wall

- Move pipe to proper elevation and angle. Installation is now complete