Manhole Lift System

The Press-Seal Manhole Lift System is an easy and safe method of placing precast concrete manholes, catch basins and other structures in the field. Inexpensive inserts are cast into the structure and reusable ductile iron locking lift eyes make the system economical and reliable. The Lift System has been tested to OSHA requirements and has more than 20 years of demonstrated safe performance. Each lift point is rated to 3600 lbs. A complete design and installation manual is available.

Document Downloads

Download Product Literature

Press-Seal Corporation can provide customized design guidelines to the precaster for the use of the lift system with their particular product

line and for its theoretical load capacity for both tensile and shear forces.

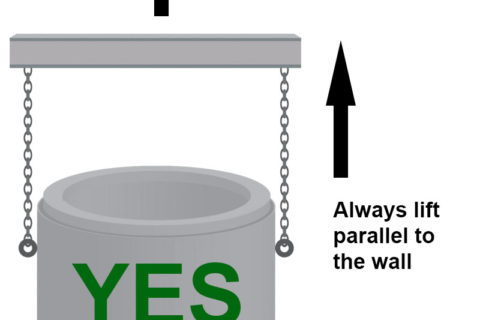

The lift system works best when inserts are placed perpendicular to the wall with the lift parallel to the wall. This method insures a safe lift and does not damage the product. Special designs can be provided for product made with more than two lift inserts.

How It Works

- Insert a lift eye into each insert.

- Turn the lift eye 90 degrees to the vertical position to lock it in place.

- Place hooks in lift eyes and lift.

Assembly

The manufacturing process is fast and simple with a Manhole Lift System:

- Place plastic insert over the assembly fixture.

- Lock insert onto fixture.

- Install the combined fixture and insert through collar into form.

- Place concrete in form and consolidate.

- Remove fixture from collar.

- Remove form from product.

Insert is now an integral part of the manhole and can be used for installation as soon as minimum required concrete strength is reached.

Where To Use

Manhole components are delivered to the field with all inserts installed and positioned for quick lifting and installation.

The lift system works best when inserts are placed perpendicular to the wall with the lift parallel to the wall. This method insures a safe lift and does not damage the product. Special designs can be provided for product made with more than two lift inserts.

Press-Seal Corporation can provide customized design guidelines to the precaster for the use of the lift system with their particular product line and for its theoretical load capacity for both tensile and shear forces.

Caution

The precaster is advised that the Lift System is designed to be used only with concrete that has achieved 4000 psi (11,730 kg/sq. cm) minimum concrete compressive strength. Also, lift insert positioning is critical for the safe and successful performance of this system. As a service to its customers, Press-Seal can recommend insert locations and maximum lift capacity for the system based on the product’s geometric configuration and material properties. When supplied, these designs will incorporate appropriate safety factors for lifting devices. Obtaining critical manufacturing strengths and tolerances, however, is beyond the capability and responsibility of Press-Seal Corporation.

-

- Place plastic insert over the assembly fixture.

- Lock insert onto fixture.

- Install the combined fixture and insert through collar into form.

- Place concrete in form and consolidate.

- Remove fixture from collar.

- Remove form from product.

Insert is now an integral part of the manhole and can be used for installation as soon as minimum required concrete strength is reached.