PSX: Direct Drive

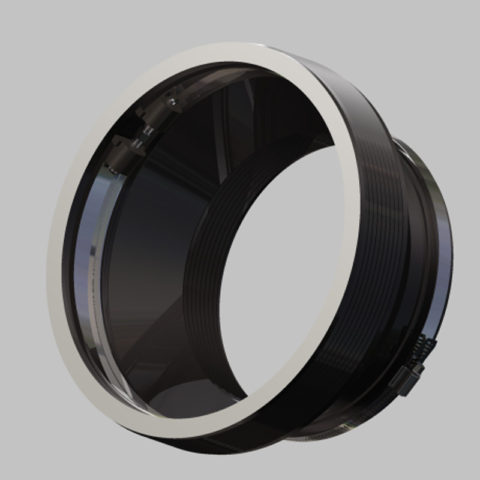

PSX: Direct Drive is a high-performance watertight pipe to manhole connector. It is the premier manhole connector in the industry for providing watertight connections to manholes and other sanitary and storm sewer structures.

- Used in wastewater and stormwater systems

- Meets or exceeds ASTM C 923, ASTM C 1244, ASTM C 1478, ASTM F 2510

Document Downloads

Download Product Literature

PSX:Direct Drive’s patented stainless steel power sleeve and adjuster installs quickly and easily providing a flexible watertight seal for the most demanding applications. It differs from most competitive manhole connectors with its all stainless steel components, no plastic parts or no welds or rivets.

If you need a manhole connector that resists common underground contaminants, the PSX: Direct Drive Nitrile would be the proper product.

How It Works

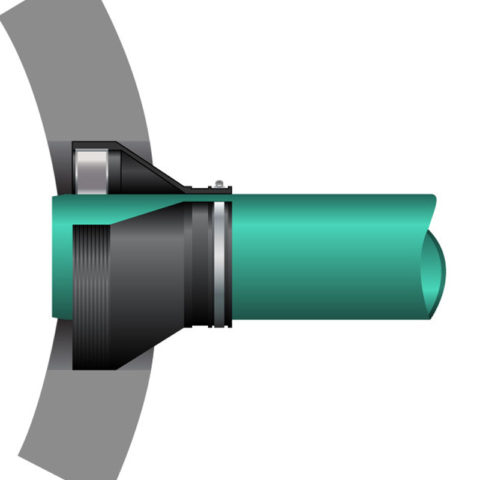

- The connector fits into a cast or cored hole.

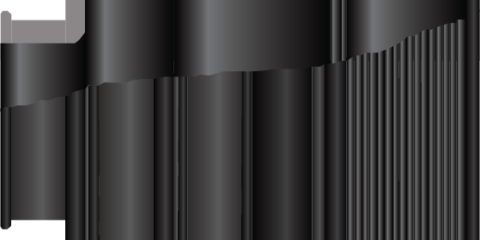

- A power sleeve made from tempered series 304 stainless steel expands with a certified installation wrench.

- Take-up clamps made from series 304 stainless steel with quick adjusting screws secure the connector to the pipe.

Why It's Better

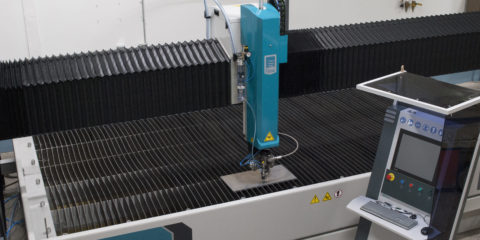

- Safely install from outside of the manhole preventing falls from crawling down into structures.

- All stainless-steel components with no welds or rivets creating a stronger product.

- Precision molding provides accurate compensation for hole size variations.

- Additional torque and multiple adjusters on larger diameters.

- Contractor can save time and money by backfilling immediately.

Where To Use

- Manholes

- Wet wells

- Square pump and lift stations

- Stormwater structures

- On-site treatment structures

- Junction chambers

- Grease interceptors

- Vaults

Meets or Exceeds

- ASTM C 923 – Standard Specification for Resilient Connectors Between Reinforced Concrete Manhole Structures, Pipes, and Laterals

- ASTM C 1244 Standard Test Method for Concrete Sewer Manholes by the Negative Air Pressure (Vacuum) Test

- ASTM C 1478 – Standard Specification for Storm Drain Resilient Connectors Between Reinforced Concrete ZPipes, and Laterals

- ASTM F 2510 Standard Specification for Resilient Connectors Between Reinforced Concrete Manhole Structures and Corrugated High Density Polyethylene Drainage Pipes

- All pipe-to-manhole and structure connections shall meet and or exceed ASTM C923, Standard Specification for Resilient Connectors Between Reinforced Concrete Manholes, Structures, Pipes and laterals.

- All mechanical devices, including castings, bolt assemblies, adjusters shall use non-magnetic 300 series stainless steel with no welds or rivets in its assemblies.

- Connector sizes less than 28” shall employ one adjuster, 28” – 34” two adjusters and 36” and larger three adjusters.

- If thermal plastic internal expansion rings are used, they must be heavy duty automotive grade material molded in one piece with an expansion installation mechanism made of a stainless steel threaded insert (not steel to plastic threads) and embedded as part of the expansion mechanism. Multiple plastic parts as part of the expansion mechanism are not allowed.

- The installation of the connector shall be accomplished at one time and shall require no additional adjustments or installation at a later time to insure a watertight seal.

- Take up clamps shall use non-magnetic 304 series stainless steel and be installed in the field using a T-Handle Torque wrench set to 60 inch-pounds and installation shall follow manufacturer’s instructions.

- The connector shall be PSX: Direct Drive and PSX: Nylo Drive as manufactured by Press-Seal Corporation of Fort Wayne, IN or approved equal.

- Prepare the hole to receive the gasket

- Clean the hole of any debris or loose dirt

- Examine the hole for any imperfections (bug holes) and wire ends in the gasket bearing surface

- Patch any voids (bug holes) with slurry

- Remove any wire protruding up into the hole and patch with slurry if needed

- Select the correct PSX: Direct Drive wrench. The wrenches and the adjusters are sized so that only the correct wrench can be used with each size adjuster, and will provide the correct torque.DO NOT USE ANY OTHER SIZE OR TYPE OF WRENCH TO INSTALL PSX: DIRECT DRIVE.

- Place the PSX: Direct Drive Connector in the hole with the adjuster mechanism in position so that it will be at the top of the hole (9 to 3 o’clock) in the final installed position of the manhole. Align the connector so that it is square to top of the hole (9 to 3 o’clock) in the final installed position of the manhole. Align the Connector so that it is square to the hole

- Place the wrench on the adjuster nut so that the arm of the wrench is on the installer’s left side. This will ensure that the proper orientation is maintained

- Begin to tighten the PSX:Direct Drive Connector by pulling the wrench handle toward the outside of the manhole. The wrench will ratchet back easily at the end of the stroke. If the connector has multiple adjusters (28” (711 mm) and higher), tighten each adjuster five times, alternating them in sequence so that installation pressure is evenly distributed

- Continue tightening until proper torque is reached. The wrench will signal this by “breaking” slightly. If in doubt torque has been reached, tighten again and wrench should “break” quickly and easily. If there are multiple adjusters, make sure that the wrench “breaks” at each one. Installation is now complete