CORE-MATIC Classic Manhole Coring Machine

EVERY CORE-MATIC CLASSIC MANHOLE CORING MACHINE INCLUDES:

- Heavy-duty duel rail frame design.

- Control/power unit can be placed on either side.

- High output hydraulic power uit with fan/radiator.

- Heavy-duty gearbox

- PLC programmed for semi-automatic coring.

- Expandable, upgradeable design.

Document Downloads

Download Product Literature Download Features

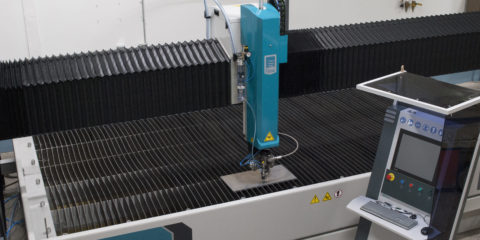

CORE-MATIC Classic Heavy-Duty Manhole Coring Machine with sliding carriage for coring product on side-by-side tables. This is a “traditional” designed coring machine where the coring tables are located at the front of the machine. If a two table design is being utilized, the coring machine traverses from table to the other.

Features and Benefits

- Multiple spindle options

- Maximum drill bit capacity of 60”

- 25 HP hydraulic pumping unit

- Multiple table options

- 72” Manhole capacity

- Choice of 1 or 4-spindle machine w/ manual operation (does not include turntable)

- Standard traversing package for CORE-MATIC Classic Machine

- Extended track traversing package for CORE-MATIC Classic Machines (5′-0′ Longer)

- Automatic control package for CORE-MATIC Machines

- Choice of either 60″, 90″ or 116″ turntable

- Horizontal pipe coring attachment

- Bit change jib crane & hoist

- Hydraulic tank heater

- Quick change hub (female)

- Quick change coupling (male)

- Bit extension, A to A flange, 6″ or 12″

- Spare turntable positioner

- One lot of barrier guards

- Power conversion to 380 VAC 50 Hz 3-phase

- CM Turntable encoder option for digital degrees readout

- 575V Electrical cross over package